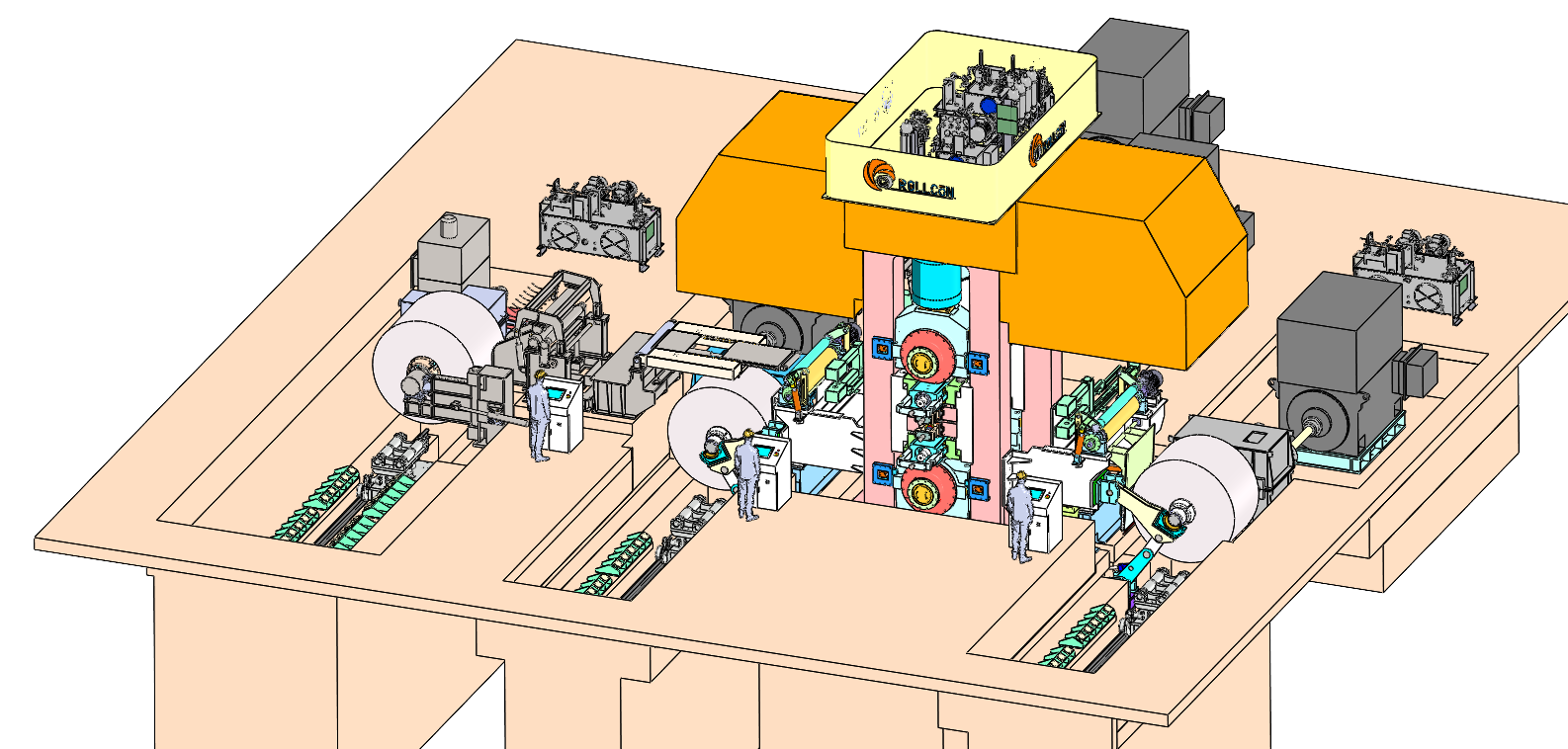

ROLLCON Engineering Co. specializes in designing and delivering state-of-the-art 2Hi, 4Hi, and 6Hi cold rolling mills tailored for processing steel and non-ferrous metals. Built for high performance and exceptional product quality, our mills support production capacities ranging from 20,000 to over 1,000,000 tons per year.

Equipped with advanced hydraulic AGC (Automatic Gauge Control), variable roll bending (VRB), zonal coolant control, and roll shifting technology, these mills ensure precise control over thickness and flatness. Our high degree of automation - driven by world-class PLC systems and digital drives from SIEMENS—enables consistent output and energy-efficient operations.

We integrate top-tier components including:

Choose ROLLCON for turnkey cold rolling mill solutions designed to deliver efficiency, quality, and long-term reliability.